Discover the various applications and popular use cases of computer vision in the manufacturing industry. Learn how manufacturing companies can leverage deep learning and AI vision technologies to implement Computer Vision for tasks such as inspection, workplace safety, factory automation, and quality control.

This article offers an insightful overview of the state-of-the-art technologies, innovative ideas for computer vision projects, real-world examples, and an industry outlook.

Applications of Computer Vision In Manufacturing

- Quality Inspection and Control

- Optimizing Supply Chains

- Equipment Monitoring and Predictive Maintenance

- Lean Manufacturing

- Safety of Workforce and Equipment

- Detecting Product Defects

- Real-time Barcode Reading

- Automated Product Assembly

- Maintaining Packaging Standards

- Pandemic Protective Measures

The Platform To Build Custom Computer Vision Systems

Viso.ai offers the leading end-to-end Computer Vision Platform, Viso Suite. Trusted by leading manufacturers and Fortune 500 companies, this automated infrastructure empowers teams to develop, deploy, and scale their computer vision applications. Request a demo for your organization today.

1. Quality Inspection with Computer Vision

Computer vision plays a crucial role in automating quality inspection processes during manufacturing. Maintaining high-quality standards is essential in the manufacturing sector, and employing deep learning and computer vision technologies can enhance accuracy while reducing human error. These technologies also contribute to operational efficiency and cost reduction.

Within manufacturing plants, computer vision can conduct inspections more quickly, accurately, and efficiently than humans. This ensures thorough inspection of every part instead of relying on random sampling. Vision systems also provide consistent standards, overcoming variations between human inspectors and improving overall efficiency in consumer product manufacturing.

For instance, a hot sauce manufacturer inspects label placement at a rate exceeding 1,000 per minute using machine vision systems trained specifically for inspection tasks. However, deep learning-based approaches offer greater flexibility and robustness.

2. Optimizing Supply Chains

Efficient supply chain management is vital for reducing costs and enhancing customer satisfaction in manufacturing plants. Computer vision applications have revolutionized tasks like warehouse management, inventory control, and overall operational efficiency within manufacturing enterprises.

For example, companies like Amazon and Walmart are exploring the use of drone systems to monitor warehouse inventories and optimize restocking through real-time camera stream processing.

3. Equipment Monitoring and Predictive Maintenance

Manufacturing plants rely on specialized equipment for production, which requires regular monitoring and maintenance to prevent defects and disruptions. Computer vision technologies excel in detecting changes and malfunctions in manufacturing equipment, enabling real-time defect recognition and timely repairs to avoid production slowdowns.

Deep learning techniques are utilized for fault diagnosis, leakage detection, and prognosis of industrial equipment, enhancing operational efficiency and reducing downtime. For instance, deep learning has been instrumental in identifying cracks in industrial components such as spherical tanks and pressure vessels in oil and gas applications.

4. Digital Lean Manufacturing

Lean manufacturing principles aim to maximize productivity and minimize waste in production operations. Industry 4.0 technologies, including computer vision, digitize lean processes, facilitate data-driven decision-making, and automate intelligent sensing technologies for improved efficiency.

According to reports from Deloitte, transitioning from traditional lean practices to digital lean manufacturing can yield significant benefits, such as annual EBITDA improvement, cost reduction per line, and enhanced general equipment effectiveness.

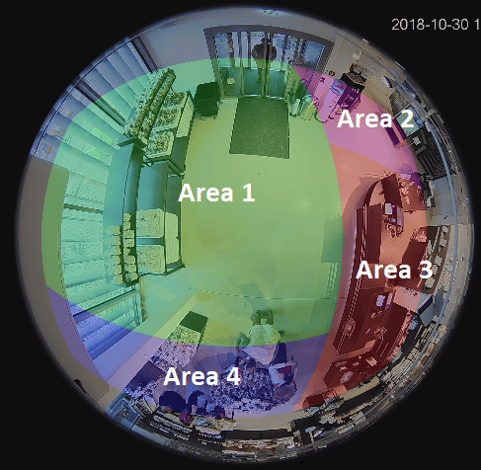

Computer vision systems are instrumental in tracking events, employee footfall, and process efficiency, enabling defect detection, and optimizing workloads on the plant floor.

Integrating computer vision into manufacturing processes can significantly enhance efficiency and productivity by reducing time, waste, and costs throughout the production cycle.

5. Safety of Workforce and Equipment

Ensuring the safety of workers in manufacturing plants is paramount for maintaining production continuity and employee well-being. Manual safety monitoring processes often fall short due to human limitations, leading to potential risks and accidents.

Computer vision technologies offer advanced safety monitoring capabilities by detecting safety breaches, generating reports, and issuing real-time alerts in case of emergencies. This proactive approach ensures a safer working environment and timely intervention by management.

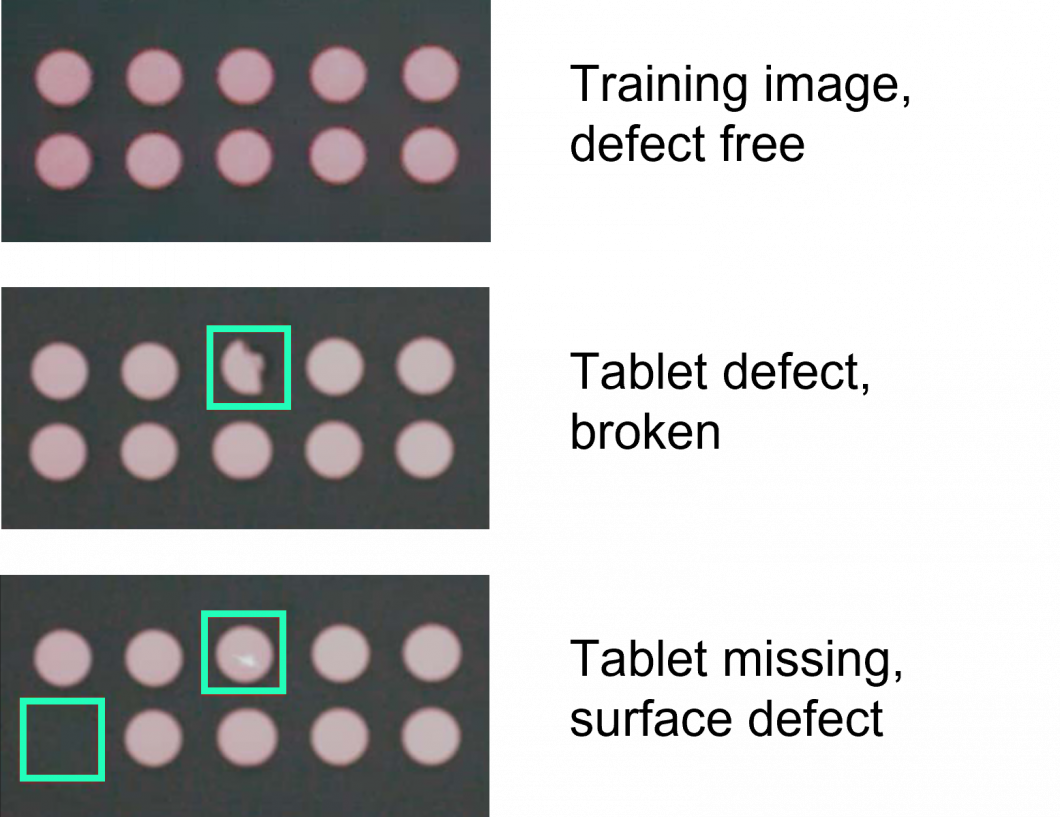

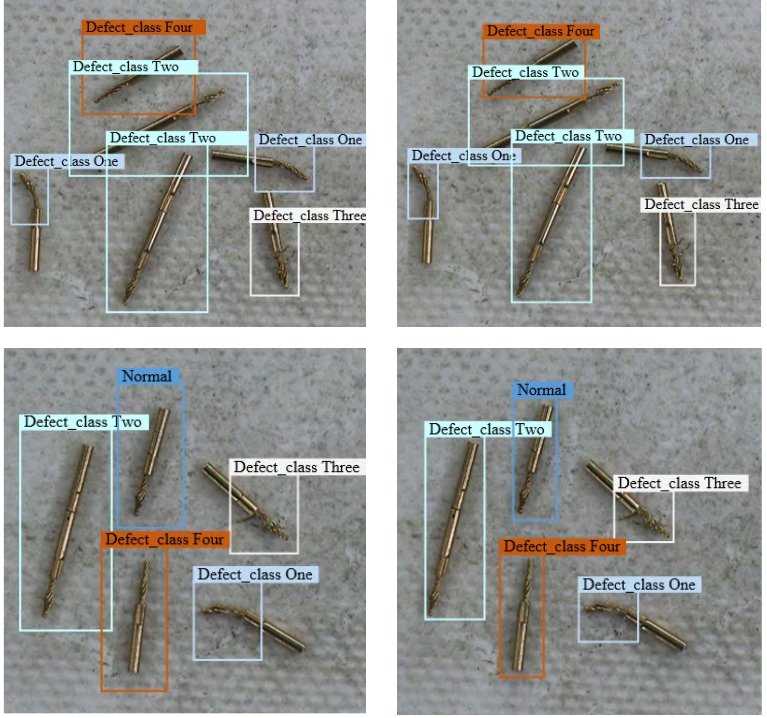

6. Detecting Product Defects

Computer vision systems are adept at identifying product defects that may go unnoticed during manual inspections, thereby preventing defective products from reaching customers. Detecting defects early in the manufacturing process is crucial for minimizing production costs and maintaining customer satisfaction.

Implementing a computer vision system for defect detection enables efficient monitoring and identification of defective pieces, ensuring high product quality standards.

Utilizing real-time deep learning systems for defect detection enhances accuracy and efficiency, preventing costly errors in production processes.

7. Real-time Barcode Reading

Accurate barcode scanning is essential for product identification and tracking in manufacturing. Computer vision systems provide a reliable solution for quickly and accurately verifying barcodes, reducing manual labor and errors associated with manual checks.

By training computer vision systems to identify faulty barcodes, manufacturers can streamline their processes and ensure accurate product labeling.

8. Automated Product Assembly

Automating product assembly processes using computer vision systems enhances accuracy and efficiency in manufacturing operations. These systems generate 3D models for precise assembly of products, particularly useful for handling delicate or intricate parts that are challenging to assemble manually.

Computer vision technology monitors and executes the assembly process with minimal errors, improving overall production efficiency.

9. Maintaining Packaging Standards

Product packaging plays a critical role in protecting goods during transportation and storage. Computer vision systems help manufacturing firms maintain packaging standards by automating tasks such as counting pieces before packaging.

In pharmaceutical applications, computer vision is essential for ensuring the correct number of tablets or capsules per bottle. These systems can detect packaging defects and deviations, ensuring consistent quality standards.

10. COVID-19 Pandemic Protective Measures

Amid the COVID-19 pandemic, manufacturing plants have implemented safety protocols such as social distancing and mask-wearing to protect workers. Computer vision applications are instrumental in monitoring compliance with these measures, ensuring a safe working environment.

For instance, computer vision models can detect social distancing violations and mask compliance, enabling proactive safety measures in manufacturing facilities.

Industry Outlook

Computer vision technology continues to transform the manufacturing industry, offering enhanced efficiency and automation across various processes. As deep learning technology advances, we can expect to see more applications of computer vision at scale, driving productivity and innovation in manufacturing.

Emerging technologies like Edge AI enable on-device processing with connected cameras, facilitating high-performance and private computer vision applications at the edge.

What’s next

If you’re interested in developing deep learning applications, explore Viso Suite, the comprehensive platform for building, deploying, and monitoring computer vision applications in manufacturing.

For more insights on related topics, stay tuned for our upcoming articles.