Smart wiring harnesses offer protective functions such as short circuit and over-temperature protection, along with reporting capabilities. These harnesses streamline vehicle wiring and eliminate the need for components like fuse boxes. They are commonly used in military, construction, commercial, and public transport vehicles, and are now making their way into light-duty internal combustion engines (ICE) and electric vehicles (EVs).

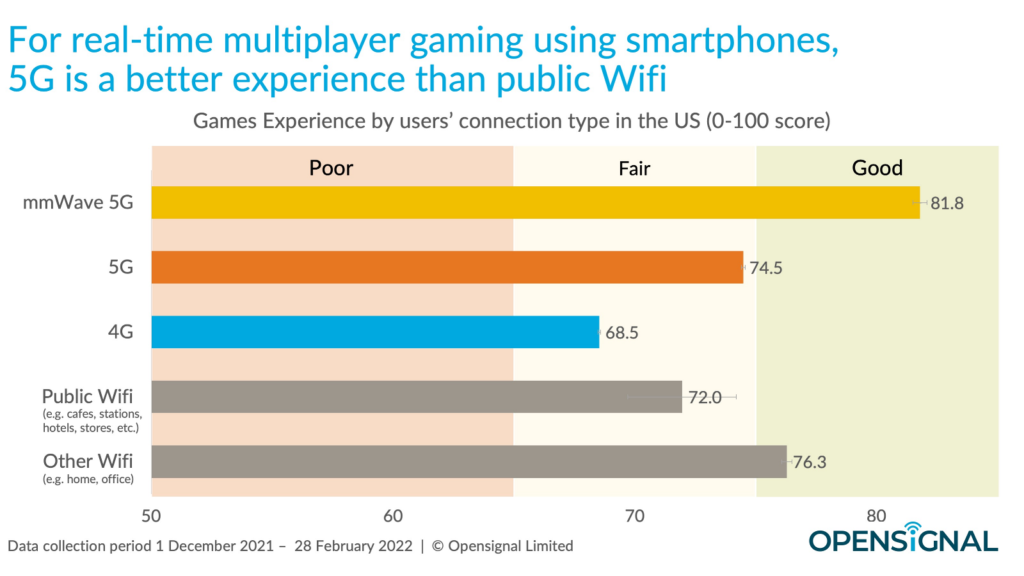

Advancements in wiring harness performance have been gradual rather than revolutionary. Technologies like the control area network (CAN), local interconnected network (LIN), and FlexRay have played a role in reducing wiring complexity (Figure 1). While CAN and LIN have simplified wiring designs, they are not ideal for safety-critical applications like wire-based braking due to their slower speeds.

Figure 1. Utilizing a CAN bus can significantly simplify wiring harnesses. (Image: NI)

FlexRay represents the next stage in this evolution, offering speeds approximately 10 times faster than CAN or LIN. This technology enables more data to be transmitted over fewer wires, reducing complexity, weight, and costs associated with wiring harnesses. The integration of smart distribution modules is the next step in enhancing harness intelligence.

Smart Distribution Modules

Smart distribution modules (SDMs) are a key feature of modern smart wiring harnesses. These modules often include a microcontroller unit (MCU) for adaptability, sensor input processing, and communication capabilities. SDMs are being developed for both low-voltage and high-voltage wiring systems, as well as specific lighting functions.

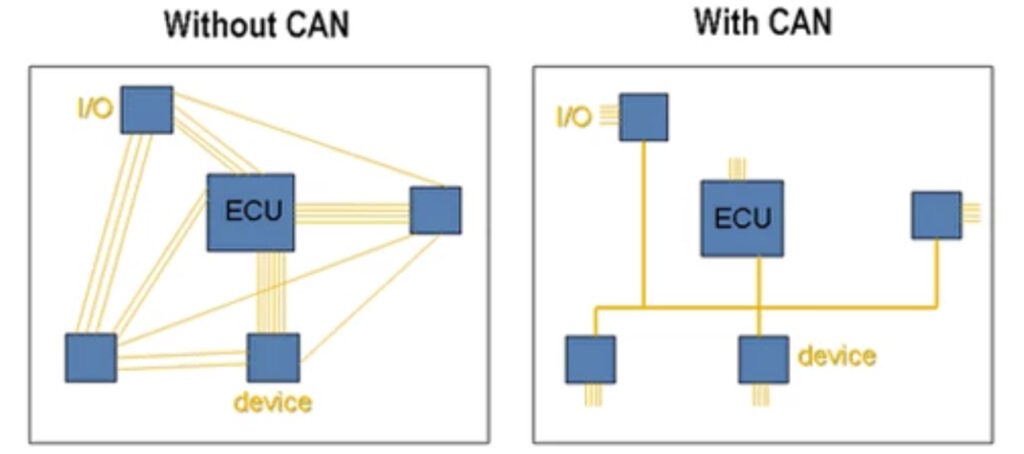

One SDM variant supports up to six channels with a power capacity of 13 A per channel. It serves as a multifunctional component, replacing switches, relays, actuators, fuses, and circuit breakers. The SDM offers advanced features like resettable and programmable electronic fuses, enhancing overall performance. The system design includes a central bus bar for power distribution and individual communication wires for each SDM (Figure 2).

Figure 2. Block diagram illustrating a smart wiring harness with multiple output SDMs (black boxes). (Image: Martin Technologies)

In addition to electronic fuses, SDMs can feature sensors for overcurrent, overvoltage, or overtemperature detection on all powered devices, with response times of less than a microsecond.

Some implementations enable communication over the power busbar, further reducing wiring complexity and weight. The system is designed to handle voltage ranges from 5 to 60 Vdc, with the option to add a high-voltage adapter board for controlling EV battery packs and drivetrain power. A fire prevention algorithm has been developed to analyze sensor data and preempt potential fire hazards.

Retrofit Harnesses for Lighting

Specialized smart wiring harnesses have been designed for adding or retrofitting LED lighting systems in vehicles. These harnesses feature a built-in microprocessor that automatically detects the existing system’s wiring configuration (positive or negative switched) and adjusts operation accordingly (Figure 3).

Figure 3. Smart harness designed for retrofitting vehicle lighting systems. (Image: Stedi)

The retrofit kit includes HB3 and H4 adapters. The HB3 adapter facilitates auxiliary lighting installations without the need for splicing or soldering to the factory wiring, often used for transitioning from halogen to LED bulbs. The H4 adapter is used for connecting headlights.

References

Controller Area Network (CAN) Overview, NI

Dual Connector Plug & Play SMART Harness High Beam Driving Light Wiring, Stedi

Martin Technologies eSPDM Smart Wiring Technology, Martin Technologies

The Wiring Harness – The Smart Communication Network in Every Car NXP

New Technology for Smart Wiring Systems, Wiring Harness News

WTWH Related links

How do EVs benefit from using zonal architectures?

Why EV makers are racing to automate wire harnesses

New high-power distribution unit for commercial EV power electronics

Smarter, safer, cheaper: How Ethernet will enable the car of the future

Modular cable assemblies to speed production of heavy-duty EVs